Best-quality materials

Precision-balanced

Quality control inspected

Multiple tooth counts available

Our Kernel Processor Roll Lineup

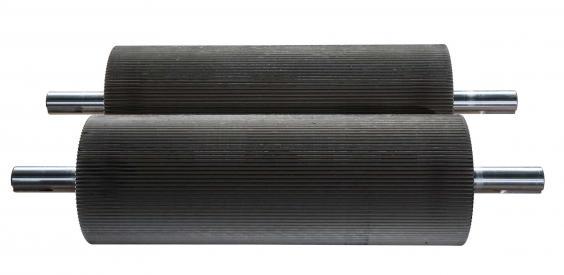

Straight Tooth Roll

The straight-tooth roll design uses a crimping action to crush kernels. As the original kernel processor roll design, the straight-tooth roll is still Old Faithful for applications such as whole crop harvesting and roller mills.

- Fine-tooth count paired with the Fibertech Chevron pattern for small-grain, whole-crop processing applications.

- Tooth configurations for nearly any application and size of milling need.

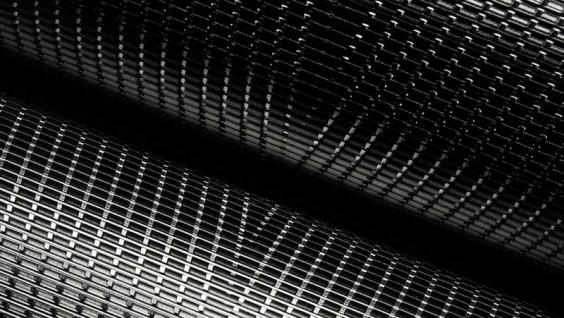

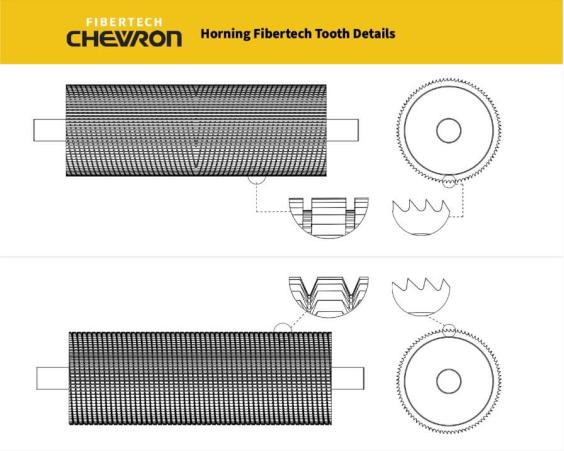

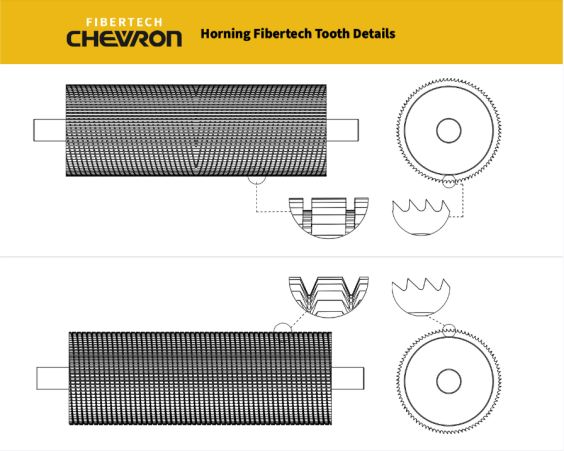

Fibertech Chevron Roll

The closer, more pronounced grooves with the chevron pattern create sharp corners on the teeth. Our patented roll design processes kernels in multiple dimensions, tearing while shearing sideways with the groove pattern.

- Less strain on your machine.

- Most intense kernel processing design on the market.

- Efficient crop mat feedthrough for maximum performance and minimum wear.

- Superior crop mat penetration at any chop length.

Sawtooth Roll

The hook on the end of the teeth transforms the smashing action of a straight-tooth roll into a slicing, ripping action that puts OEM rolls to shame. These powerful teeth, combined with a wider gap, make this roll a market leader in capacity.

- Less strain on your machine.

- Process kernels in one dimension.

- Less stalk processing than grooved designs.

- Power-efficient; great for older, lower-power machines.

- Superior crop mat penetration compared to competing sawtooth options.

Designed for speed differential. This differential maximizes the effect of the hooked tooth design. As the forage hits the gap, the hooked teeth on each roll—one faster, one slower—disintegrate the cob, chopping the kernel into a consistent meal of tiny granules.

Power efficiency & less stress on your machine. The sawtooth design allows a wider gap between rolls because it processes so thoroughly.

| Straight Tooth | Fibertech Chevron | Sawtooth | |

|---|---|---|---|

| Preferred speed differential ranges | 40-50%+ * | 40-50%+ * | 40-50%+ * |

| Recommended roll tooth spacing | 6 / whole crops like wheat, milo, etc.(com- bined with Fibertech) | 4 - 4.5 3.5 - 4.5 | 4 - 4 4 - 4.5† |

| Milling outcome | Recommended only for wholecrop or Earlage. | Disintegrated grain and cobs with the stalk ligaments split.** | Good kernel and cob processing; limited stalk processing.** |

| Grooves per inch | 4 - 10 We only stock grain rollers in the straight tooth for roller mills. | 3.5 / 4 / 4.5 | 4 4.5 for some models |

| Recommended roll gap | Roll gap varies drastically depending on crop conditions and moisture. A good starting point is 1/16” or 1.5 - 2 mm. Make sure e-stop (if available) is set as tight as possible without rolls touching. |

*Older models may only be able to get 30-32% differential.

**Varies depending on speed difference.

† Available in select models.

Quality Materials for the Long Haul

Each Horning roll is:

- Constructed with premium, selectively sourced alloys–closely monitored through manufacturing and meticulously inspected before shipping.

- Expertly balanced to an extremely close tolerance. Shaft and roll body alike are engineered to run perfectly smoothly.

- Heat-treated to harden the steel for enhanced wear resistance.

- Available in chrome plating for up to 3 times the wear life. (All Fibertech rolls come with chrome plating.)

Explore the Fibertech Chevron Roll Industry leader in kernel processing effectiveness

Farmers say this patented roll is a game changer. It combines the best of dual cut and sawtooth technologies to provide optimum cob grip and aggressive kernel processing. The spirals spin out from the center, distributing stress balance across the roll. This reduces end wear and enhances feedthrough. It’s easy on your machine.

Connect your horsepower to tonnage. The Fibertech Chevron roll is extremely power efficient on a per-ton basis.

Why a square tooth matters. We use a specific process in our rolls’ milling production to create a sharp, square-tooth edge. Other manufacturers’ rolls have a sloped tooth wall with slightly rounded tooth edges. Fibertech’s square effect, coupled with a high-capacity sawtooth design, causes peerless aggression in unwrapping the stalk's cellulose fibers and penetrating the crop mat for outstanding KP quality and consistency.

A nutritionist’s dream, a farmer’s problem solver, and a custom operator’s sidekick. This roll stands at the intersection of farm profitability, optimized nutritional value, and in-the-field harvest rigors.

The process Horning uses in the milling production of our rolls creates a sharp, square tooth edge. Other rolls have a sloped tooth wall and slightly rounded effect to the edges of the tooth. The square effect, coupled with the Horning's Hi-capacity sawtooth profile design creates a peerless aggregation in unwrapping the cellulose fibers of the stalk, and penetrating the crop mat for outstanding KP quality and consistency.

Connecting Your Horsepower to Tonnage

“As well as reducing waste and optimising silage quality, Horning’s FiberTech Chevron rollers can improve milk yields and butterfats, says Harvesting Solutions UK general manager Alan Haycocks.” –Sarah Kidby, UK Farmers Guide

4 Key Factors to Put You at the Top of Your Dairy Nutrition Game

How can you reach kernel processing scores that optimize nutrition, health, and milk production in dairy cows? In addition to a great kernel processing unit, you’ll need to understand, implement, and monitor these four key factors–roll condition, tooth spacing, tooth style, and speed differential.

Kernel Processor Rolls’ FAQs

Horning® Parts Finder

Can't find the rolls you need? Horning® offers rolls to fit many brands and models, and is always expanding our product line. Contact us, and we will be happy to help. In fact, we can create custom rolls for you.