43.201225, -96.264059

Kooima Ag

2642 Rock Ridge Rd

Rock Valley, IA 51247

Sunday: Closed

Monday: Closed

Tuesday: 7:00 am-5:00 pm

Wednesday: 7:00 am-5:00 pm

Thursday: 7:00 am-5:00 pm

Friday: 7:00 am-3:00 pm

Saturday: Closed

Northern , Iowa - Eastern, Minnesota - Eastern, Kansas - Eastern, South Dakota

Products we carry

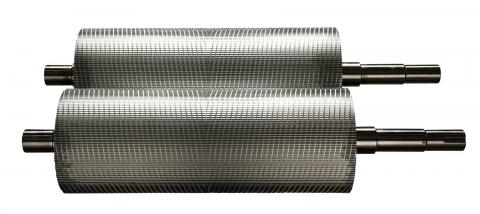

As an authorized dealer, we carry the full line up of the Horning Mfg. family of quality corn harvesting products including 2 row and 3 row rotary row independent cornheads, complete kernel processor kits for pull-type machines and replacement rolls to fit pull-type processors such as New Holland®, John Deere®, Gehl® and Dion®. Each Horning® line is engineered for its specific use to bring you best possible value. Replacement kernel processor rolls from are available in industry leading Fibertech or high-capacity sawtooth designs. They will fit many brands including Krone®, New Holland® , John Deere® and Claas®. Horning’s stationary electric rollermill is available in three models for small to mid sized operations, grinding approximately 40 lbs. of corn per minute – that’s up to 800 bushels an hour! It is available with several tooth configurations - for course corn cracking to small grains and can be purchased with a bagger for high-moisture corn. Ready to get cracking? Contact us now and we’ll help you match the correct product for your application.